Heat Recovery Crematech

Because a lot of heat is generated during cremation, we always work with our clients to see if this heat can be used within the crematorium. For example, to heat water (for the central heating system) or to use the excess heat for cooling. In consultation with the client’s installer, we look for the most optimal solution.

Heat is generated in two ways from an electric cremation system. First, the cremation oven itself radiates heat (even when not in use), which is transferred to the surrounding space. Second, heat is generated during cremation in the form of flue gases.

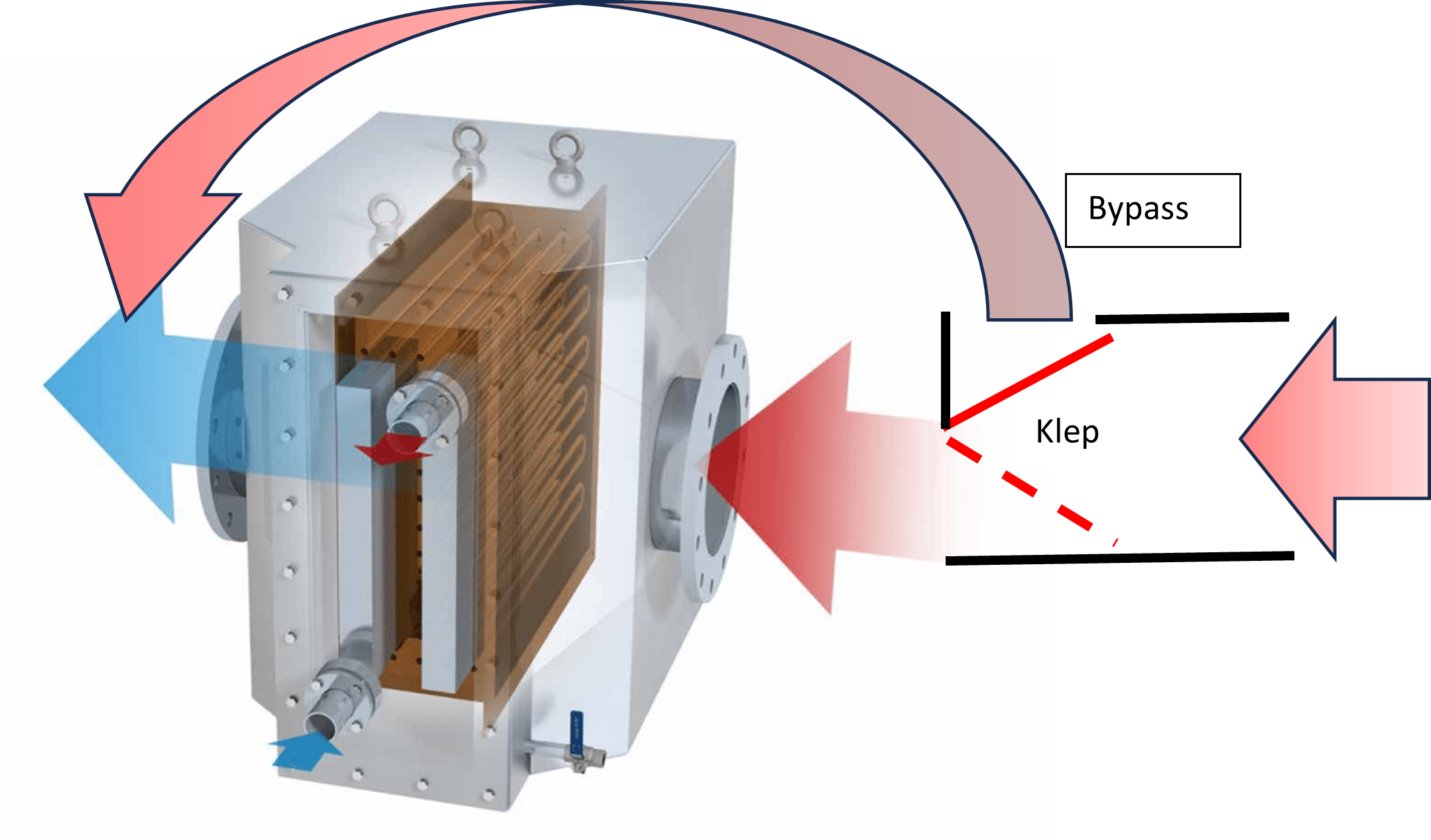

Crematech Heat Exchanger

The radiant heat emitted into the surrounding space can be efficiently used for a heat pump. When the heat pump is placed near the cremation oven, its efficiency greatly increases. The heat produced during cremation can be recovered using a heat exchanger. In this process, the filtered, clean hot flue gases are passed over the heat exchanger, which heats water. When both systems are applied, the heat released is optimally recovered and reused. It is important, however, that there is demand for this heat.

There are several significant advantages of the Crematech heat exchanger system compared to other systems in the market:

- The Crematech heat exchanger is placed in the clean section of the filter system, which means that maintenance is practically negligible. This is in contrast to flue gas coolers, which require regular cleaning.

- Heat is only extracted from the flue gases when there is actual demand for heat. If there is no demand, the flue gases are not passed over the heat exchanger. As a result, there is no need for a dump cooler to dissipate the unnecessary recovered heat, which would also consume energy.

The estimated maximum power generated per cremation is approximately 70-80 kWh*. This means that with three cremations per day, about 210 kWh can be generated.

(*Average, based on an already warmed filter system.)